It seems the Mk II wreck loses some more rusty bits every time I take a photograph of it.

My Jaguar XJ6 2.8

maandag 15 augustus 2011

The gas tanks

The gas tanks need urgent attention.

The seller of the car already told me the left hand side tank was leaking. I've poured some (old) gasoline in it and here's the result after a couple of minutes:

Some of the horrible sludge that came out of the "good" tank when I took the sender out and there was more petrol in it than I had thought...

There are two possible approaches: buy new tanks (in which case I'll probably have to buy new senders and maybe even new fuel pumps to fit the only replacement that still exists) or try to repair these. Matthys sells kits to derust, degrease and coat tanks, and even little holes should be no problem. I'll keep you updated.

I went for the largest kit (110-170 liters) because I figure I can do both tanks *and* the Mk II tank with this kit.

Both senders are defective. I've only taken out one of them (the one from the good tank) and one of the conductors (metal strips) had sheared off. They can be soldered. This isn't my best soldering ever but it was only a trial. I have to take out the sender again when I coat the tanks.

The seller of the car already told me the left hand side tank was leaking. I've poured some (old) gasoline in it and here's the result after a couple of minutes:

Some of the horrible sludge that came out of the "good" tank when I took the sender out and there was more petrol in it than I had thought...

There are two possible approaches: buy new tanks (in which case I'll probably have to buy new senders and maybe even new fuel pumps to fit the only replacement that still exists) or try to repair these. Matthys sells kits to derust, degrease and coat tanks, and even little holes should be no problem. I'll keep you updated.

I went for the largest kit (110-170 liters) because I figure I can do both tanks *and* the Mk II tank with this kit.

Both senders are defective. I've only taken out one of them (the one from the good tank) and one of the conductors (metal strips) had sheared off. They can be soldered. This isn't my best soldering ever but it was only a trial. I have to take out the sender again when I coat the tanks.

New head gasket

There were water leaks from the head gasket so instead of waiting for worse, I've decided to change it right away. This also gave me a chance to change the carbs' diaphragms easily.

I've also replaced some of the core plugs that were corroded. Some of them only required a mild tap with a screwdriver to break.

The valve springs were replaced as well (I'm hoping the ticking noises will stop) and I've ordered some new shims as valve clearance was too little for almost every valve.

I took the head out with the inlet manifold (minus air filter) in place. The outlet manifold was removed separately along with the first downpipe.

Bottom view of the head.

Head back in place, manifolds and cam shafts to follow...

I've also replaced some of the core plugs that were corroded. Some of them only required a mild tap with a screwdriver to break.

The valve springs were replaced as well (I'm hoping the ticking noises will stop) and I've ordered some new shims as valve clearance was too little for almost every valve.

I took the head out with the inlet manifold (minus air filter) in place. The outlet manifold was removed separately along with the first downpipe.

Bottom view of the head.

Head back in place, manifolds and cam shafts to follow...

Various

Some miscellaneous things....

While waiting for the new shims to arrive, I've used egg cartons to keep the tappets and their shims in the right order.

The carbs' gaskets had been replaced but there was still a small leak so I've decided to replace the springs and the diaphragms. Not a bad idea as it turned out.

I'm taking the seats to Amsterdam to have them reupholstered (There was a special action at http://www.bekledingexpress.nl/ - so my brother Filip took them out of the car. Apparently the whole interior is held in place with 10 screws.

Filip also took out the radio and heater controls in order to reach the vacuum distributor for the heating. I'm changing all the vacuum hoses, they seem pretty deteriorated.

While waiting for the new shims to arrive, I've used egg cartons to keep the tappets and their shims in the right order.

The carbs' gaskets had been replaced but there was still a small leak so I've decided to replace the springs and the diaphragms. Not a bad idea as it turned out.

I'm taking the seats to Amsterdam to have them reupholstered (There was a special action at http://www.bekledingexpress.nl/ - so my brother Filip took them out of the car. Apparently the whole interior is held in place with 10 screws.

Filip also took out the radio and heater controls in order to reach the vacuum distributor for the heating. I'm changing all the vacuum hoses, they seem pretty deteriorated.

Boot light

As you probably remember, the boot light didn't light up and the mercury tilt switch (the orange thingy) was the culprit.

I found that the Comus AG3011-0 is the right switch for the job. It can handle 1A at 12-24V. Even getting it in place was pretty easy.

But first I got it wrong. If you mount it this way, the light would only go on if you're on a steep incline ;-)

This is the correct way. I've soldered a small copper ring to the end to make better contact with the lamp. The brown spacer is the original one minus the wire in the center. The original spring could also be re-used. Soldering a wire on the rounded side was surprisingly easy. Heat-shrinkable tube is indispensable unless you want to blow a fuse every time you open the boot.

And there it is. It's a shame the housing was damaged a little by the vise and pliers I had to use to open it, but once the lamp is back in place, nobody will notice.

By the way, the light *does* go out when the boot lid is closed, I've checked.

woensdag 27 juli 2011

Prop shaft rattle

Although I am a rather patient person, the prop shaft on this car has tested my patience to the limits and if there is a God above, he will have heard his name mentioned a couple of times in ways he's rarely heard.

I knew the centre bearing mounting was defective so I got the entire mouting out. The bracket you see here in my hand is normally attached to the rubbers. In an attempt to minimise the problem a previous mechanic had tried to put a rubber grommet of some sort between the mounting plate and the chassis. You can see it on the left. Of course this didn't help any so I've removed it.

New bushings - a couple of cents each - are always a pleasure to compare with the old ones.

So far so good - although this job alone had taken a while already. After I had put everything back in place I found one of the universal joints to be very jiggly. Apparently one of the UJ's cups had lost all it's needles. So *that's* where the distinct "klonk" came from every time I changed from reverse to forward or vice versa.

In theory, changing these universal joints isn't all that difficult. Of course, it tends to get more difficult the older the car is. And keeping the needles in place while tapping the cups in isn't easy either. So, to cut a long story of agony short, it took me about two or three hours to change a couple of universal joints and put the prop shaft back in (again).

Later on, I started to realise that there was "something" about the position of prop shafts. And then it struck me: I had removed the prop shaft from the splined shaft after the first universal joint, and neglected to make marks as to how it had come out. A quick check, and indeed the shaft was mounted incorrectly, about 90° wrong. Apparently, this can lead to surprising driving behavior. *!§@!!#!

This time I decided to leave the centre bearing and to remove just the part between the splined shaft and the centre bearing. This time I made a mark where the flanges meet in the centre so I can mate them again the way they were. Of course, the nuts and bolts were rusty and not accesible with a socket wrench. Darn it to heck! (to put it very mildly). The Dremel had to come in to remove the nuts.

And some more darnation. With the exhaust in the way I couldn't get the shaft in the splines the way it was supposed to be. So - you've guessed it - the front of the exhaust had to come loose. Mercifully, these bolts were rather easy to undo. After that things went pretty easily. I did replace the original bolts with metric size bolts with Allen heads. This way, I could fasten them with a ratchet in a matter of minutes.

I took the car for a short test drive (although the engine is still running rough) and the "klonk" and "dakadakadaka" sounds are gone. Finally.

I knew the centre bearing mounting was defective so I got the entire mouting out. The bracket you see here in my hand is normally attached to the rubbers. In an attempt to minimise the problem a previous mechanic had tried to put a rubber grommet of some sort between the mounting plate and the chassis. You can see it on the left. Of course this didn't help any so I've removed it.

New bushings - a couple of cents each - are always a pleasure to compare with the old ones.

So far so good - although this job alone had taken a while already. After I had put everything back in place I found one of the universal joints to be very jiggly. Apparently one of the UJ's cups had lost all it's needles. So *that's* where the distinct "klonk" came from every time I changed from reverse to forward or vice versa.

In theory, changing these universal joints isn't all that difficult. Of course, it tends to get more difficult the older the car is. And keeping the needles in place while tapping the cups in isn't easy either. So, to cut a long story of agony short, it took me about two or three hours to change a couple of universal joints and put the prop shaft back in (again).

Later on, I started to realise that there was "something" about the position of prop shafts. And then it struck me: I had removed the prop shaft from the splined shaft after the first universal joint, and neglected to make marks as to how it had come out. A quick check, and indeed the shaft was mounted incorrectly, about 90° wrong. Apparently, this can lead to surprising driving behavior. *!§@!!#!

This time I decided to leave the centre bearing and to remove just the part between the splined shaft and the centre bearing. This time I made a mark where the flanges meet in the centre so I can mate them again the way they were. Of course, the nuts and bolts were rusty and not accesible with a socket wrench. Darn it to heck! (to put it very mildly). The Dremel had to come in to remove the nuts.

And some more darnation. With the exhaust in the way I couldn't get the shaft in the splines the way it was supposed to be. So - you've guessed it - the front of the exhaust had to come loose. Mercifully, these bolts were rather easy to undo. After that things went pretty easily. I did replace the original bolts with metric size bolts with Allen heads. This way, I could fasten them with a ratchet in a matter of minutes.

I took the car for a short test drive (although the engine is still running rough) and the "klonk" and "dakadakadaka" sounds are gone. Finally.

The electrics

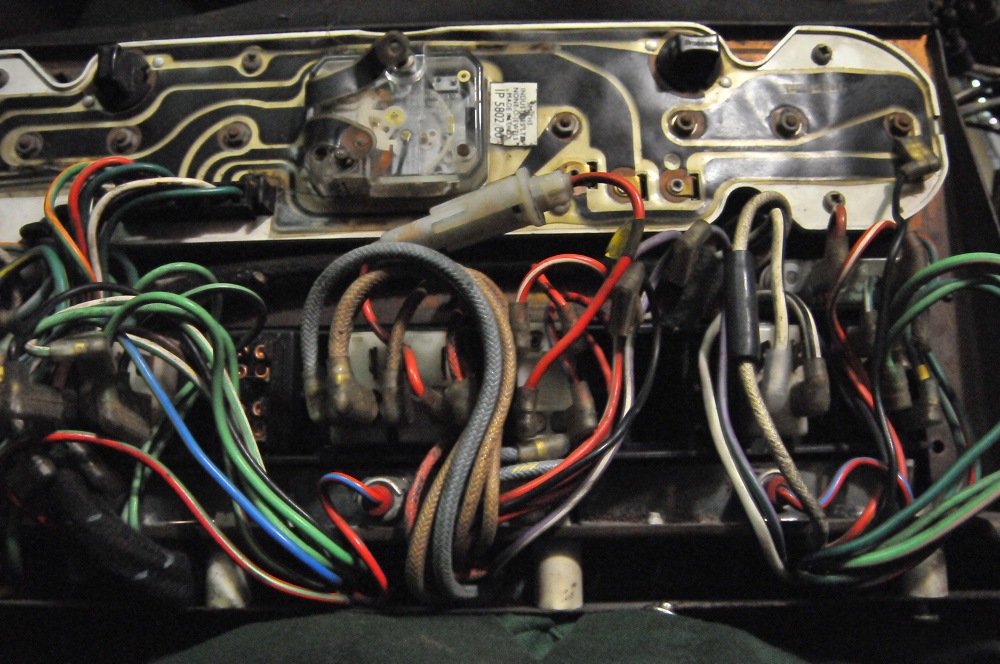

Some of the switches on the instrument panel weren't in their place as solidly as should be. Some of the plastic rims that hold the switches had broken off, but there was a spare switch holder between the salvage parts I'd got with the car. It took little under an hour to replace the whole thing, starting with carefully noting which wire went where.

The switch panel is out.

And this is the replacement one. Apparently the pieces of white tape on the green foil are there because the little lamps are right behind those places and the light has to be more or less the same across the indication strip.

Then I've tackeled another problem which the previous owner's mechanic couldn't quite figure out: neither the boot light nor the reversing lights worked. The man had spent some time with the wires in the boot, but it turns out the wiring wasn't the problem.

The boot light seemed to be getting power but even with a new bulb it didn't light up. I've dismantled the socket and here are the components:

The orange thing is a tilt switch that's supposed to switch on the light when the boot lid is opened. This switch doesn't make contact anymore. It's no longer available - probably because it contains mercury. I've been looking around for a (non-mercury) tilt switch that can handle 1 Amp - most of them seem to be for small electronics applications and can hardly switch any power. I may have found a source, but I'll update once I'm sure it works.

As for the reversing lights: the switch was the culprit. The switch is depressed by a piece of plastic on the selector lever. Apparently the switch wasn't sensitive enough.

These switches are relatively easy to open. I've cleaned the contacts and elevated them a little. Works like a charm now. The switch is still available new as well, but this is the cheapest solution.

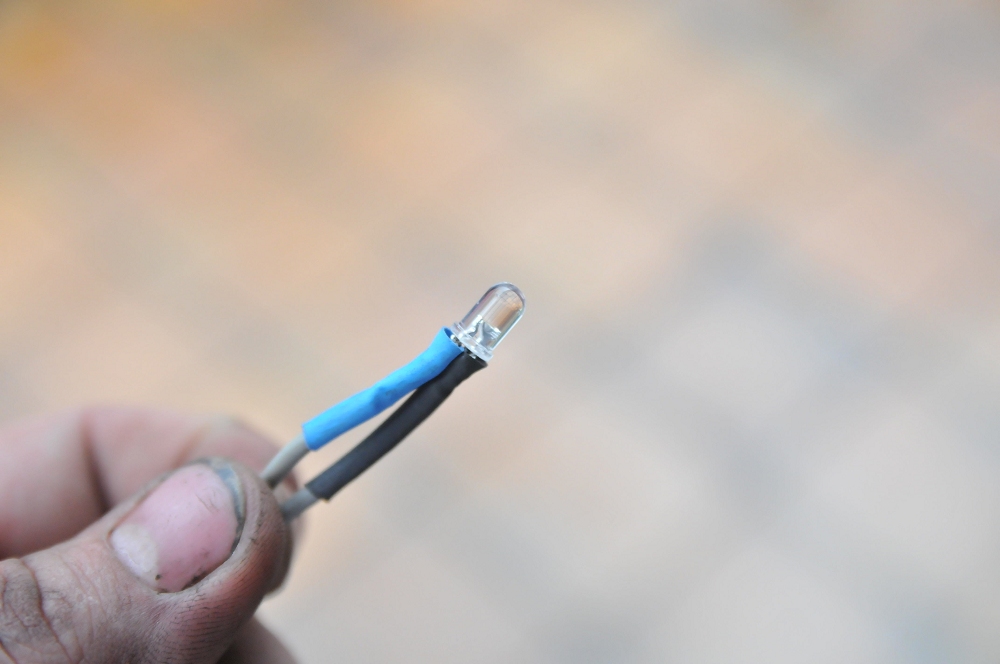

As you may have noticed in the previous pictures, the selector light about which I've posted earlier (the repair with the ball point pen) has been removed again. It broke down very easily. After a couple of hours of cursing and trying, I've found the final solution.

This requires a white high-intensity led. Available from any electronics store. In one of the heat shrinkable tubes (doesn't matter which one) is a 1k resistor. Observe the led's polarity!

This finely threaded hollow rod is used in certain lighting fixtures to screw sockets on. I suppose it's available in DIY shops.

An exact and easy fit.

Oh, a sidenote: I've replaced both flasher units (there's one for "normal" and one for hazard warning). The Haynes manual says there's one on the right and one on the left of the steering column, but I suppose that's for RHD cars since on mine both were to the left of the steering column. Here they are, indicated with the circles. The arrows point to a couple of inline fuses that are easily overlooked. One of them is for the selector light and cigar lighter light.

The switch panel is out.

And this is the replacement one. Apparently the pieces of white tape on the green foil are there because the little lamps are right behind those places and the light has to be more or less the same across the indication strip.

Then I've tackeled another problem which the previous owner's mechanic couldn't quite figure out: neither the boot light nor the reversing lights worked. The man had spent some time with the wires in the boot, but it turns out the wiring wasn't the problem.

The boot light seemed to be getting power but even with a new bulb it didn't light up. I've dismantled the socket and here are the components:

The orange thing is a tilt switch that's supposed to switch on the light when the boot lid is opened. This switch doesn't make contact anymore. It's no longer available - probably because it contains mercury. I've been looking around for a (non-mercury) tilt switch that can handle 1 Amp - most of them seem to be for small electronics applications and can hardly switch any power. I may have found a source, but I'll update once I'm sure it works.

As for the reversing lights: the switch was the culprit. The switch is depressed by a piece of plastic on the selector lever. Apparently the switch wasn't sensitive enough.

These switches are relatively easy to open. I've cleaned the contacts and elevated them a little. Works like a charm now. The switch is still available new as well, but this is the cheapest solution.

As you may have noticed in the previous pictures, the selector light about which I've posted earlier (the repair with the ball point pen) has been removed again. It broke down very easily. After a couple of hours of cursing and trying, I've found the final solution.

This requires a white high-intensity led. Available from any electronics store. In one of the heat shrinkable tubes (doesn't matter which one) is a 1k resistor. Observe the led's polarity!

This finely threaded hollow rod is used in certain lighting fixtures to screw sockets on. I suppose it's available in DIY shops.

An exact and easy fit.

Oh, a sidenote: I've replaced both flasher units (there's one for "normal" and one for hazard warning). The Haynes manual says there's one on the right and one on the left of the steering column, but I suppose that's for RHD cars since on mine both were to the left of the steering column. Here they are, indicated with the circles. The arrows point to a couple of inline fuses that are easily overlooked. One of them is for the selector light and cigar lighter light.

Abonneren op:

Posts (Atom)